Now Reading: How 3D-Printed Prosthetics Are Transforming Lives: Innovations in Affordable Limb Replacement

-

01

How 3D-Printed Prosthetics Are Transforming Lives: Innovations in Affordable Limb Replacement

How 3D-Printed Prosthetics Are Transforming Lives: Innovations in Affordable Limb Replacement

The field of prosthetics is undergoing a groundbreaking transformation with 3D printing technology, bringing new hope to individuals in need of limb replacements. This revolutionary approach is not only reshaping how prosthetics are designed and manufactured but also making them more accessible and affordable, particularly in underserved communities.

Traditional prosthetics can cost thousands of dollars and take weeks, even months, to produce. In contrast, 3D-printed prosthetics are highly cost-effective, with some models costing as little as $50 to $100. They are also customizable, lightweight, and can be produced in a fraction of the time. For people in low-income regions or war-torn areas, these benefits are life-changing, allowing amputees to regain mobility and independence without incurring huge expenses.

The range of 3D-printed prosthetics is expanding rapidly, catering to various needs:

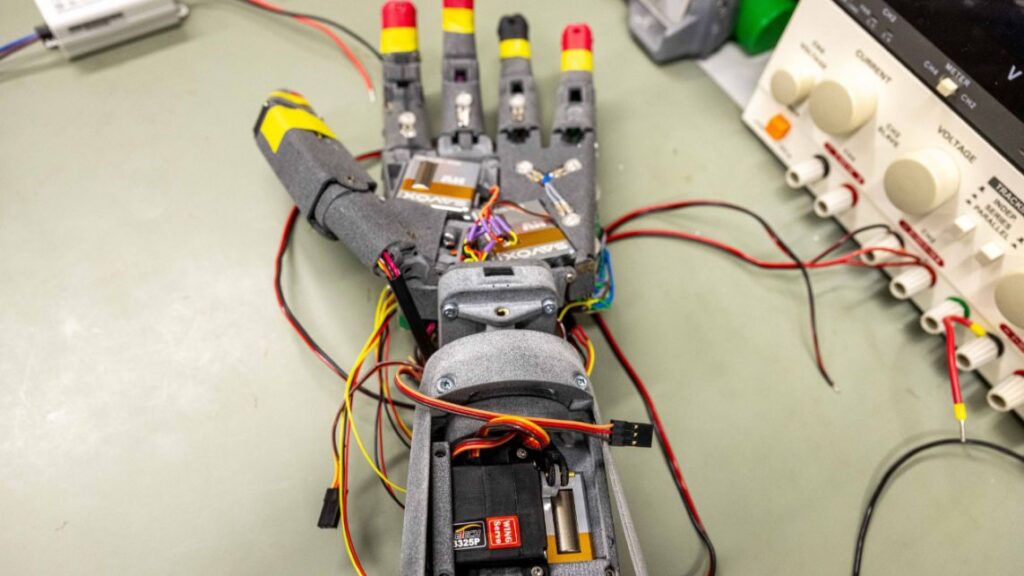

1. Upper-Limb Prosthetics: These include hands, fingers, and forearms. They can be designed for functional use, like gripping objects, or for aesthetic purposes, mimicking natural limbs.

2. Lower-Limb Prosthetics: Designed for walking and mobility, these include feet, legs, and even custom-fit sockets for enhanced comfort.

3. Assistive Devices: Specialized tools like finger extensions or partial hand replacements for those with specific injuries or deformities.

Custom Designs for Every Need : One of the most exciting aspects of 3D-printed prosthetics is their adaptability. Using a 3D scanner, healthcare providers can capture precise measurements of a patient’s limb, creating a prosthetic that fits perfectly. Open-source designs have made this process even more accessible, allowing communities to share and improve prosthetic blueprints.

Making a Global Impact: Organizations like E-Nable and startups across the globe are harnessing 3D printing to meet local healthcare needs. In some cases, schools, universities, and even hobbyists have joined the effort, building prosthetics for children or veterans who would otherwise lack access to this life-altering technology.

Challenges and the Road Ahead: While 3D-printed prosthetics are promising, they aren’t without challenges. Issues such as durability, material strength, and regulatory approval need to be addressed for widespread adoption. However, advancements in materials like carbon fiber composites and stronger polymers are paving the way for more reliable solutions.

A Revolution in Progress: As 3D printing technology continues to evolve, the future of prosthetics looks incredibly bright. With innovations in robotics, sensor integration, and advanced materials, prosthetics are becoming more lifelike and functional than ever before. The potential to restore not just physical capabilities but also confidence and dignity is driving this technology forward.

For a detailed look into the world of 3D-printed prosthetics, visit the an article by All3DP:

The Most Common 3D-Printed Prosthetics.