The field of orthotics in Pakistan has long relied on traditional methods for designing and manufacturing orthotic devices. However, with the advent of 3D printing technology, there is a growing interest in its application to create more efficient, cost-effective, and customized solutions. While Pakistan’s healthcare system has faced many challenges in incorporating advanced technologies, 3D printed orthotics is emerging as a promising innovation that could revolutionize patient care for individuals with disabilities or physical impairments.

The Current Landscape of Orthotics in Pakistan

Orthotics is a specialized field within rehabilitation medicine that involves designing external devices, such as braces and supports, to aid in the correction or prevention of musculoskeletal deformities. In Pakistan, the majority of orthotic devices are still being produced using conventional methods. These include plaster casting, manual fabrication, and the use of prefabricated components. Though effective, traditional manufacturing often results in lengthy production times and limited customization, which can hinder patient outcomes.

Prosthetic and Orthotic Services in Pakistan: According to a 2022 report by the Pakistan Society of Rehabilitation Professionals (PSRP), over 30,000 people in Pakistan require orthotic devices annually. The demand is particularly high among pediatric patients, trauma victims, and individuals with disabilities due to conditions like cerebral palsy, spina bifida, and polio. However, access to quality orthotic care remains limited, especially in rural and underserved regions.

The Role of 3D Printing Technology

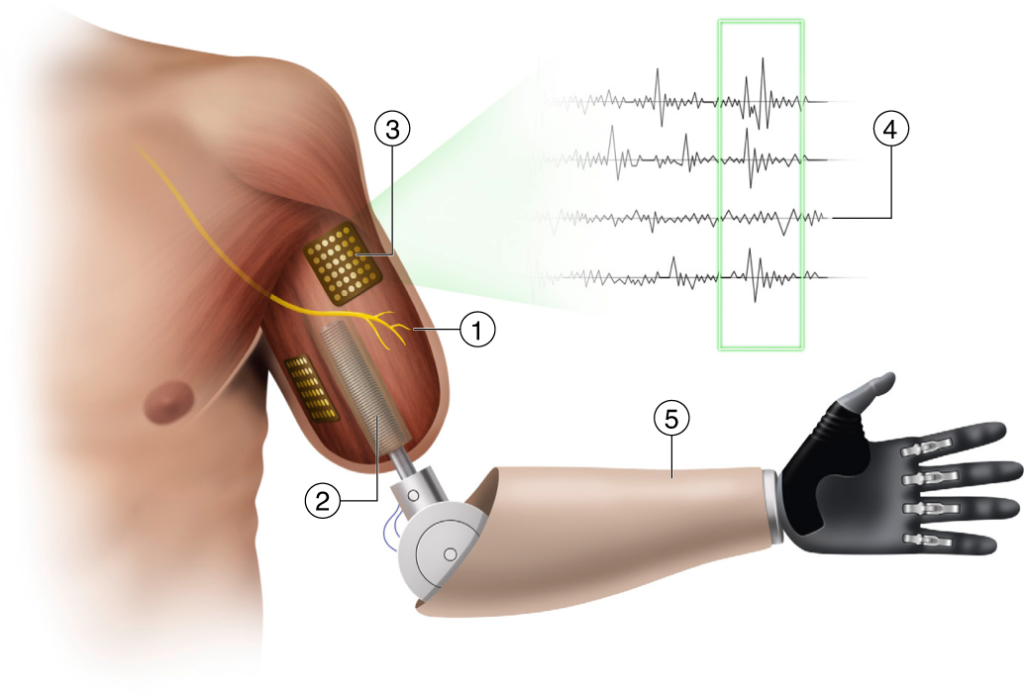

3D printing, also known as additive manufacturing, offers a game-changing alternative to traditional orthotic production. This technology allows for the creation of highly customized orthotic devices by using digital models and advanced materials. The process starts by scanning the patient’s body part, followed by designing a digital orthotic model that is tailored to fit their unique anatomy. The device is then printed layer by layer using specialized 3D printers.

Advantages of 3D Printed Orthotics:

- Customization: 3D printing allows for precise, patient-specific designs, which ensures a better fit and improved functionality.

- Cost-Effectiveness: While the initial cost of 3D printing technology may be high, it has the potential to reduce long-term costs by speeding up production and minimizing material waste.

- Faster Production Times: Traditional orthotic manufacturing can take weeks, whereas 3D printed orthotics can be produced within days.

- Lightweight Materials: 3D printed orthotics are often lighter than traditional devices, improving patient comfort and mobility.

Adoption in Pakistan

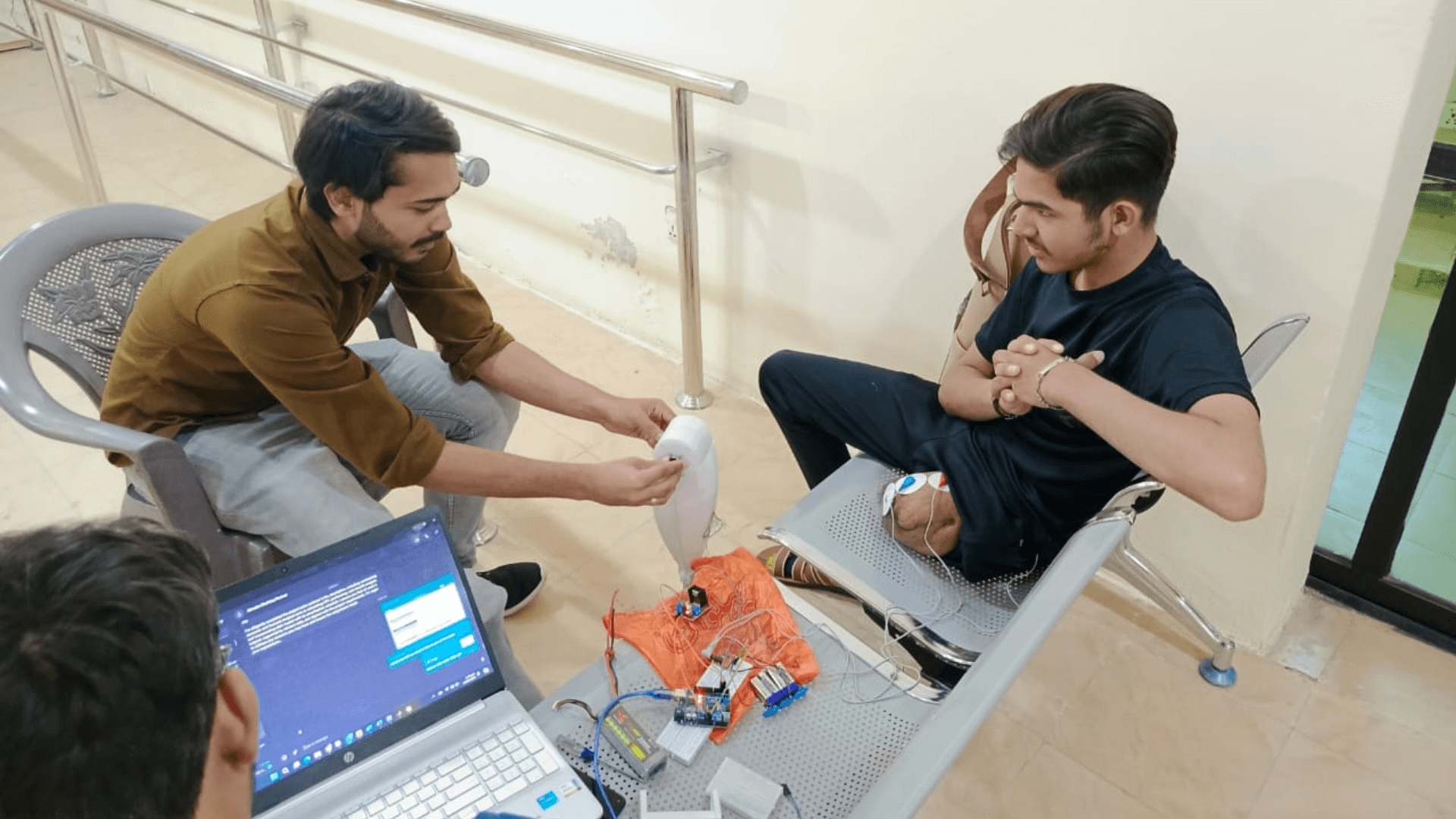

The adoption of 3D printing in Pakistan’s healthcare sector is still in its early stages, but several organizations and institutions are exploring its potential. The National University of Sciences and Technology (NUST) has been at the forefront of research in 3D printed prosthetics and orthotics. In recent years, they have collaborated with international partners to explore the feasibility of introducing affordable 3D printed solutions to the local market.

Additionally, private healthcare providers in urban areas like Karachi, Lahore, and Islamabad have started offering 3D printed orthotic services. These services are primarily available through specialized clinics, although they remain limited in scope and accessibility.

Challenges in Implementation

Despite the promise of 3D printed orthotics, there are several challenges hindering widespread adoption in Pakistan:

- Cost: While 3D printing can reduce production costs in the long term, the upfront investment in equipment and training is significant. Many clinics and hospitals, particularly in public healthcare, lack the financial resources to acquire this technology.

- Training and Expertise: The implementation of 3D printing in orthotics requires specialized knowledge in both the medical and technical fields. Currently, there are few training programs available in Pakistan for professionals to acquire the necessary skills.

- Awareness and Trust: The general public and healthcare professionals are not yet fully aware of the benefits and reliability of 3D printed orthotics. Building trust in this new technology will require education and successful case studies.

Future Prospects

There is great potential for the growth of 3D printed orthotics in Pakistan, especially with increasing awareness of its benefits and the expansion of healthcare technologies. Government support, in terms of subsidies or grants for healthcare innovation, could play a crucial role in accelerating adoption.

Moreover, international partnerships and collaborations with global organizations could bring down the cost of technology and provide training opportunities for local professionals. With the right investments, Pakistan could see a significant improvement in the accessibility and quality of orthotic care in the coming yearss.

3D printing technology offers a promising future for orthotics in Pakistan. It has the potential to transform patient care by providing faster, more affordable, and customized solutions. While the technology is still in its early stages of adoption, increasing awareness, investment, and training will be key to unlocking its full potential. As Pakistan continues to modernize its healthcare infrastructure, 3D printed orthotics could play a vital role in improving the quality of life for thousands of patients.

References

- Pakistan Society of Rehabilitation Professionals (PSRP) Report, 2022.

- “Advancing Healthcare through 3D Printing in Pakistan,” National University of Sciences and Technology (NUST), 2023.

- World Health Organization (WHO), “Assistive Technology in Developing Countries,” 2021.